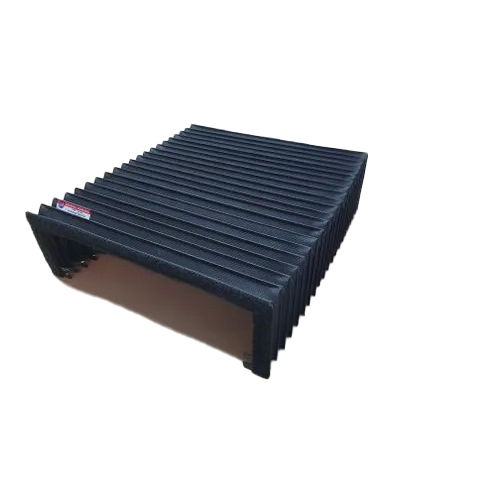

Loading Spout Bellow cover

Product Details:

- Head Code Round

- Max. Temperature -30 - 550 degree Celsius (oC)

- Usage Cement Plant, Power Plant,

- Technique Forging

- Size 1-15

- Product Type Bellow Cover

- Weight 10-50 Kilograms (kg)

- Click to View more

Loading Spout Bellow cover Price And Quantity

- 01 Piece

- 5000 INR/Piece

Loading Spout Bellow cover Product Specifications

- Black

- Forging

- 10-50 Kilograms (kg)

- -30 - 550 degree Celsius (oC)

- 1-10 Mtr Meter (m)

- Round

- 10-200 mm Millimeter (mm)

- 1-15

- Bellow Cover

- Cement Plant, Power Plant

Loading Spout Bellow cover Trade Information

- 100 Piece Per Week

- 1 Week

- Wooden Box

- All India

- ISO 2008:2015

Product Description

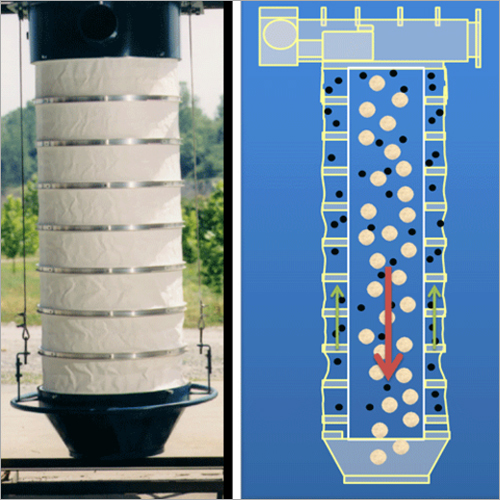

Loading spout bellow offered by Gurukripa Engineering is positioned towards the inlet spout of the taker. Lowering of this bellow depends on the position of its outlet cone. When its outlet cone is positioned on the inlet spout of the tanker, its externally located slack cable switch ( fitted at the exterior of its transmission box) ceases to lower the bellows. As its result, limit switch which is located at the interior of transmission box tends to stop extending and contracting the bellow. Loading of material tends to start with the opening of silo outlet valve.Polymer based coating of the outlet cone of the bellow serves as an effective sealing option against dust at the time of filing of the tanker. During this period, filter fan tends suctioning dust through the bellows when the tanker lowers its height under the effect of excessive material weight. The outlet cone is used to install level monitoring system. This monitoring apparatus sends alarm regarding the maximum level of material that can be stored inside the tanker and indicates about closing of silo outlet valve instantly. The bellow tends to get back its stand by position by contracting itself in case of delay for around 10 seconds occurs. Within this period, the filter is left to vacate remaining dust particles inside it. When the bellow is in its fully contracted position, cable limit switch located inside the transmission box ceases to function. The filter cartridge is allowed to go through pulse jet cleaning process for 10 minutes.

Technical Reference of Loading Spout Bellow:

- Inlet diameter: 300 mm - 1200 mm

- Maximum throughput rate: 250 m3/h (147 cfm)

- Operating temperature: -40 - 150 degree C (-40 - 300 degree F)

- Filter surface: 10 m2 (108 sq ft)

Comprises of in built dust filter to minimize dust emission while loading process is going on The chute is covered with neoprene material of Hypalon brand for making bellow weather protected. Moreover, this chute is high temperature protected and is abrasion proof.Tanker level status is indicated by inside level controller of reverse cone. When the tanker is completely full, bellow is loaded to ensure about equal material distribution inside the tanker. Loaded bellows are moved upward and downward directions by using two lifting cables located outside. Movement of bellow does not cause any wear of electrical cables.

Product details of Loading Spout Bellow:

- Material Grade : SS201,304

- Phase : Single Phase

- Thickness : 0.5-2 mm

- Voltage : 750 kV

- Material : PVC

- Brand : Gurukripa Engineering

- Color Black

- Warranty : 12 months

- Usage/Application : Bulk loading,Cement Plant,Flashash loading-Unloading

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+